Moulding Materials

A Bioplastics that Seamlessly Integrated to your Running Machine

Transitioning away from plastic shouldn’t slow you down

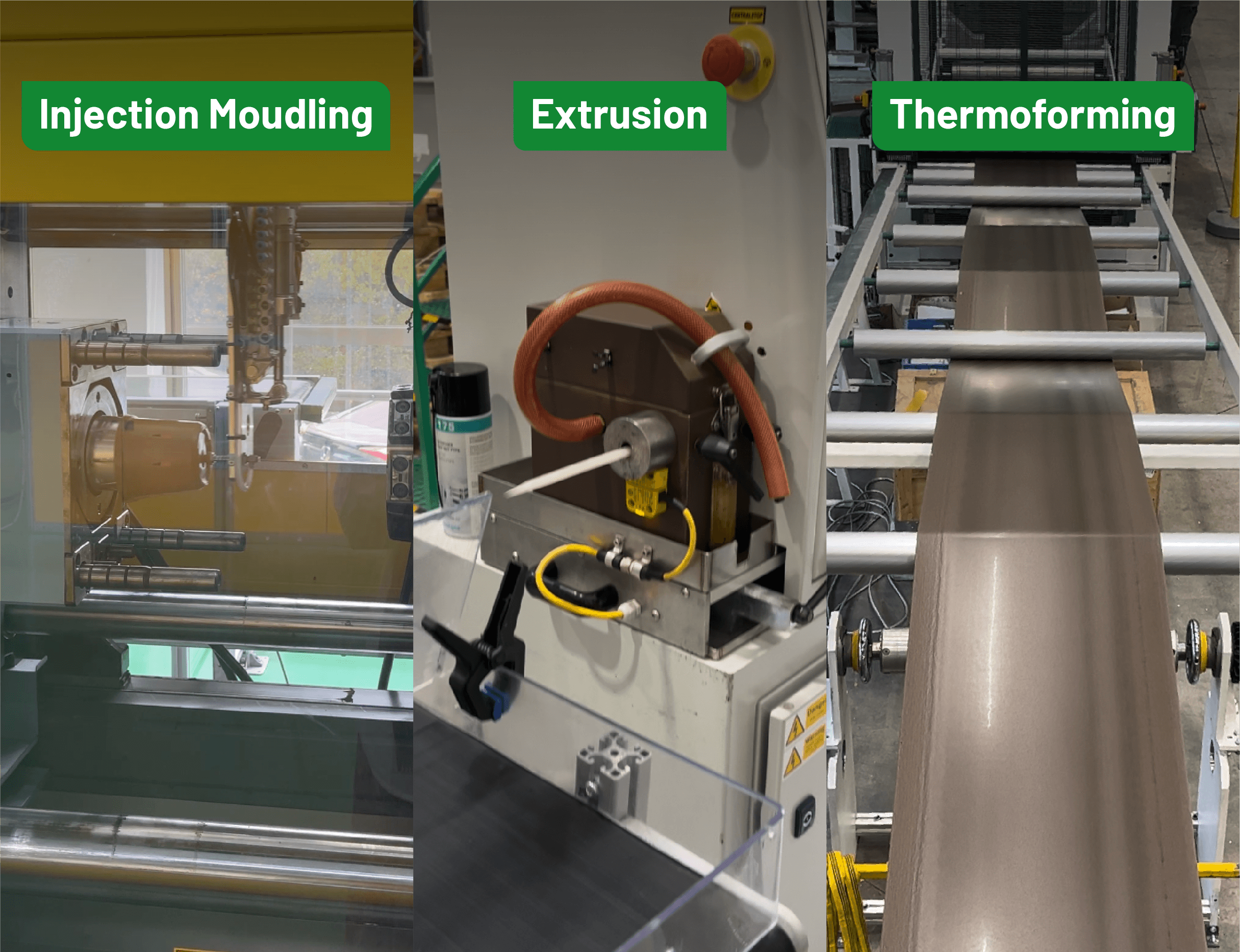

Plug & Play: Solinatra runs on your existing moulding, thermoforming, and extrusion equipment.

No New Tooling: Keep your current production lines – no capital investment required.

Frictionless Switch: From converters to OEMs, integrate Solinatra effortlessly into your workflow.

Unmatched Performance: Get plastic-like efficiency, but with none of the environmental baggage.

Discover Our Materials

Moulding Materials

Materials

What our materials can do

We make an impact together with our partners

✺ Frequently asked questions ✺

-

Solinatra materials are designed to run on standard injection moulding, thermoforming, and extrusion equipment. There’s typically no need to modify your lines or invest in new tooling. Need guidance? Our technical team supports every step. Contact here!

-

Solinatra softens at slightly lower temperatures than some plastics, so minor temperature adjustments may improve performance. Contact us for specific technical guidelines tailored to your set-up. Contact here!

-

Solinatra is engineered for efficiency, matching plastic’s throughput and finish. Our partners report no loss in cycle time or product quality. Plus, you’ll be delivering plastic-free results with every run. Contact here!

-

Yes, Solinatra coffee capsules are certified industrially and home compostable (TÜV OK Compost, and more). They’re 100% biobased and leave behind no microplastics.

-

Contact our team for free samples, a production trial, or a technical consultation. We’re here to help you make the transition effortless.

-

More integration and technical FAQs available here.