The Meaning Behind #MakesItAlright: Solinatra’s No Harm Material

Solinatra is built on one principle: no harm. Not less harm. Not reduced harm. Not harm offset later. Solinatra is designed so the material itself does not leave a problem behind. This is the standard we believe single-use products and packaging should meet, and it is why Solinatra exists in the first place.

From that principle comes #MakesItAlright. It is our way of saying that when something is made with Solinatra, it should feel safe to choose and safe to stand behind. It means the material does not create hidden trade-offs that brands have to explain, defend, or manage later. The decision becomes simpler because the outcome is clear: packaging that performs without leaving harm behind for the environment, compliance, or operations.

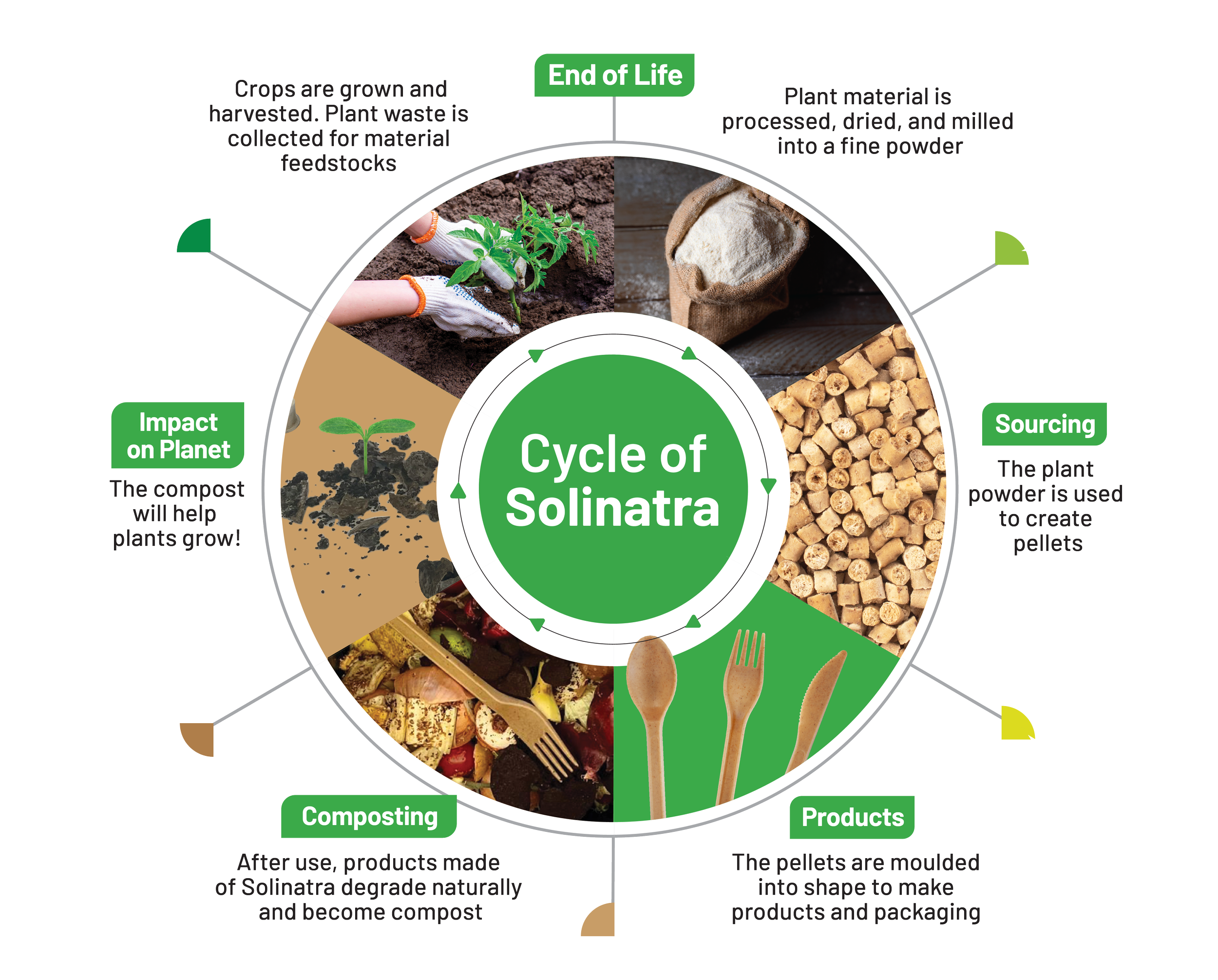

Environment: Solinatra is designed for a circular economy

Solinatra Cycle

Solinatra is #MakesItAlright for the environment because it is built as a full circular material cycle, not a one-way product. It begins where nature already produces value. Crops are grown, and agriculture generates byproducts that are often treated as waste. Solinatra uses these agricultural byproducts as a resource, transforming them into Solinatra pellets that can be processed into packaging and product forms.

After use, Solinatra is designed to return through biodegradation and composting rather than remain as long-term waste. It becomes biomass that can nourish soil and support new growth, helping crops grow again and continuing the loop. This is Solinatra’s circular economy cycle in its simplest form: grown, repurposed, formed, composted, grown again. A material designed to finish its job and return responsibly, so nothing harmful remains.

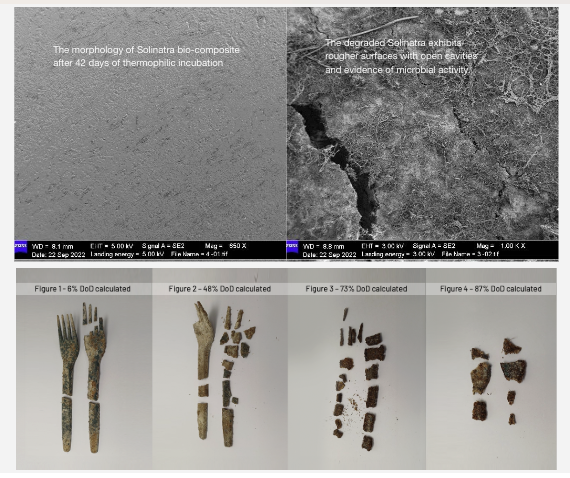

Law & Compliance: Built to meet standards, proven to break down

Solinatra is #MakesItAlright for compliance because it is engineered to align with recognised standards and certification pathways. Brands should not have to guess whether their packaging choice will be accepted, challenged, or questioned in different markets. Solinatra is compatible with established certification standards, including compostability and bio-based content, helping brands move forward with confidence.

But compliance is not only about certifications. It is about end-of-life reality. Solinatra is designed to break down through the right scenarios rather than remain intact or fragment into persistent pollution. This is why we show breakdown imagery: it demonstrates a clear outcome. The material degrades, disintegrates, and shows evidence of microbial activity over time. In other words, Solinatra does not remain as plastic, and it does not leave harm behind in the environments where waste actually ends up.

Solinatra under the microscope and degradation process

This is what “alright” means for law and compliance: a material built for approvals, built for proof, and built for real-world end-of-life.

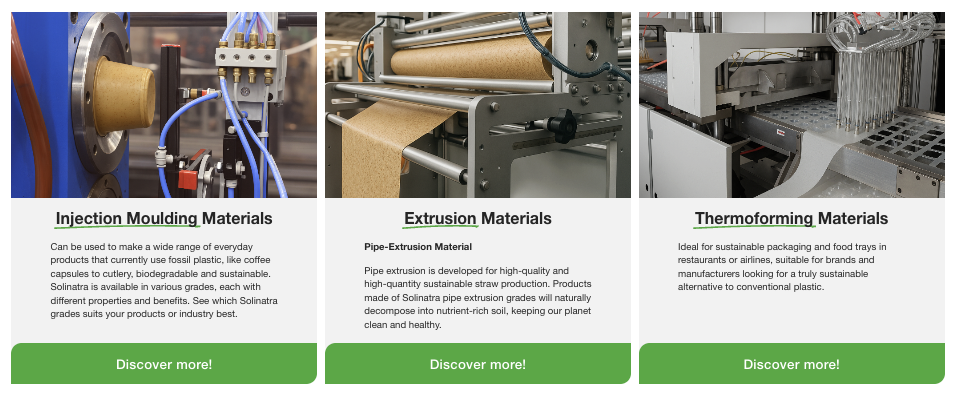

Processing: Compatible with standard equipment

Solinatra is #MakesItAlright for processing because it is designed to work with manufacturing equipment that producers already rely on. Brands should not have to reinvent production lines or adopt complicated new methods to switch away from plastic. Solinatra is compatible with standard industrial processing methods, including injection moulding, thermoforming, and extrusion, making it scalable and practical for real-world manufacturing.

Solinatra materials compatible with standard equipment